Factories

Partners

Machines

Benefits Of Industrial 4.0-

Break Down Data Silos

Single source of truth principles allow user to access information from a single source

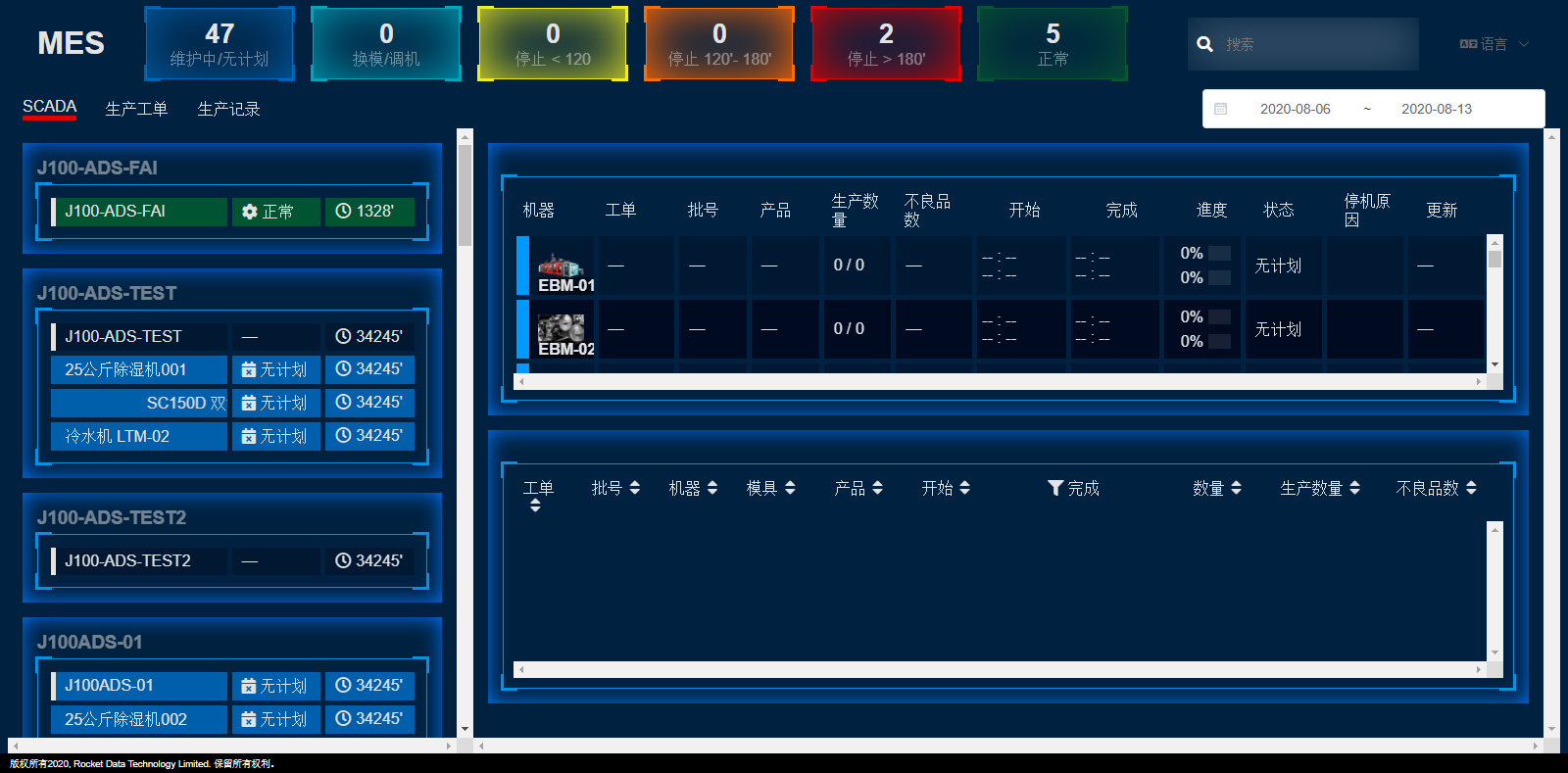

Improved Productivity

Identify highest waste in the factory and improvement measures can be taken

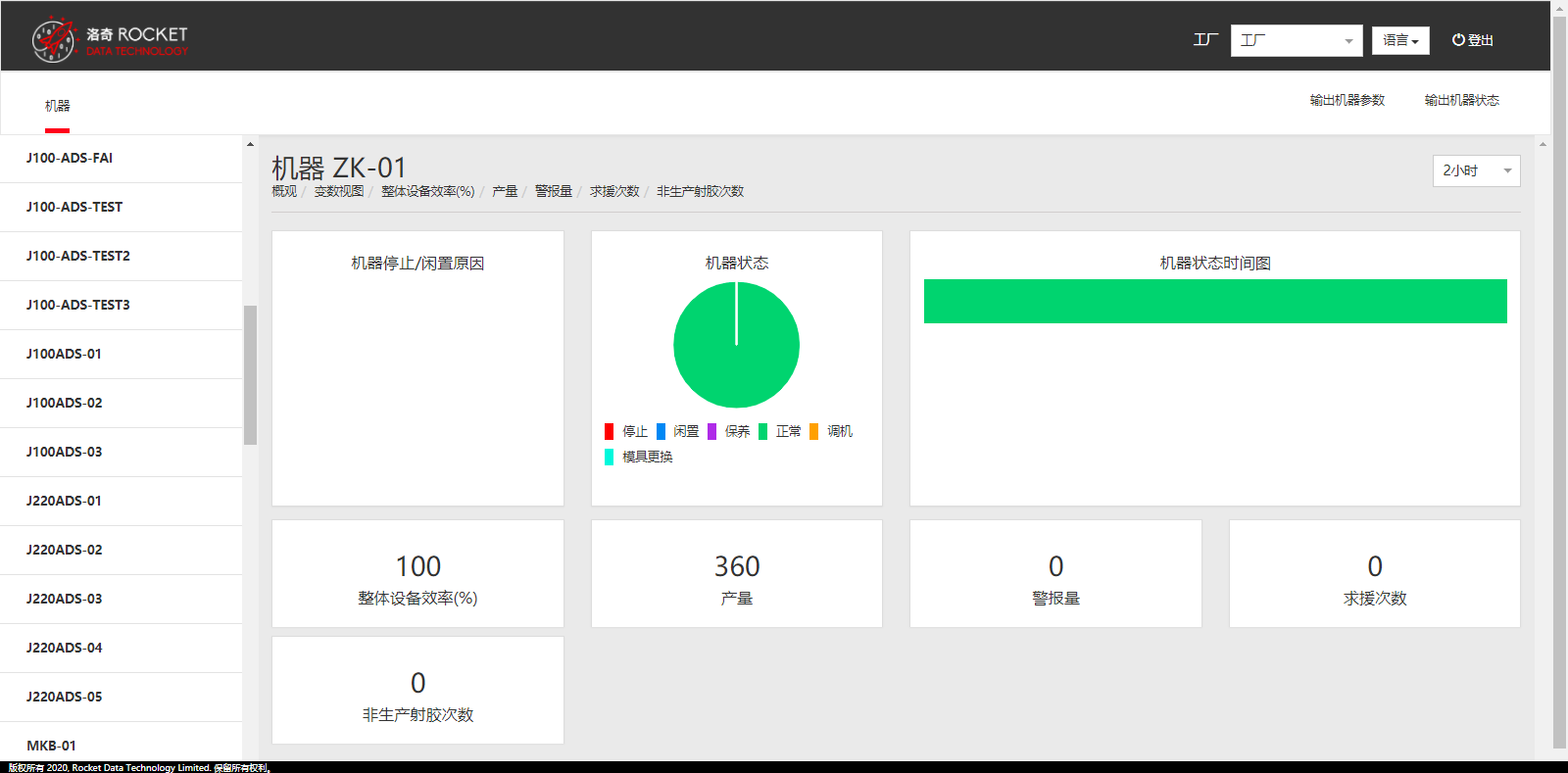

Real-Time Monitoring

Real-time machines’ status and OEE can be monitored immediately

Data Automation

High speed data extraction minimizes manual intervention and increased data reliability

Why Choosing Us

We have stronger and more complete systems.

Plug-and-Play System

Both software and IoT devices can be setup and ready to use on the same day

Smart Data Analytics

Smart data analytics modules helps organizations to make data-driven solutions and improve business-related outcomes

Future Proof

Constant future software features updates. API integration is also available for integrating existing system

Cost Efficient

Low cost manufacturing solution with ROI guaranteed

How It Works

Machines & Devices

Machines are connected either by using RJ45 ethernet cable or converter

Edge Computing Device (ECD)

Edge computing device is plug-and-play ready and can connect to different types and brands of machine instantaneously

Machine data is collected and securely to the ECD

Secured Cloud Hosting

A well-built cloud platform integrates the use of enterprise-grade security management systems to protect your data and reduce security threats

End User

Rocket SmartPack provides end user production insight via mobile app and web browser

Factor Connect System Value

Reduce Machine Downtime

Single source of truth principles allow user to access information from a single source

Improve Production Efficiency

From planning department to maintenance department, fast and accurate to giving insights and allow user to make decision before hand

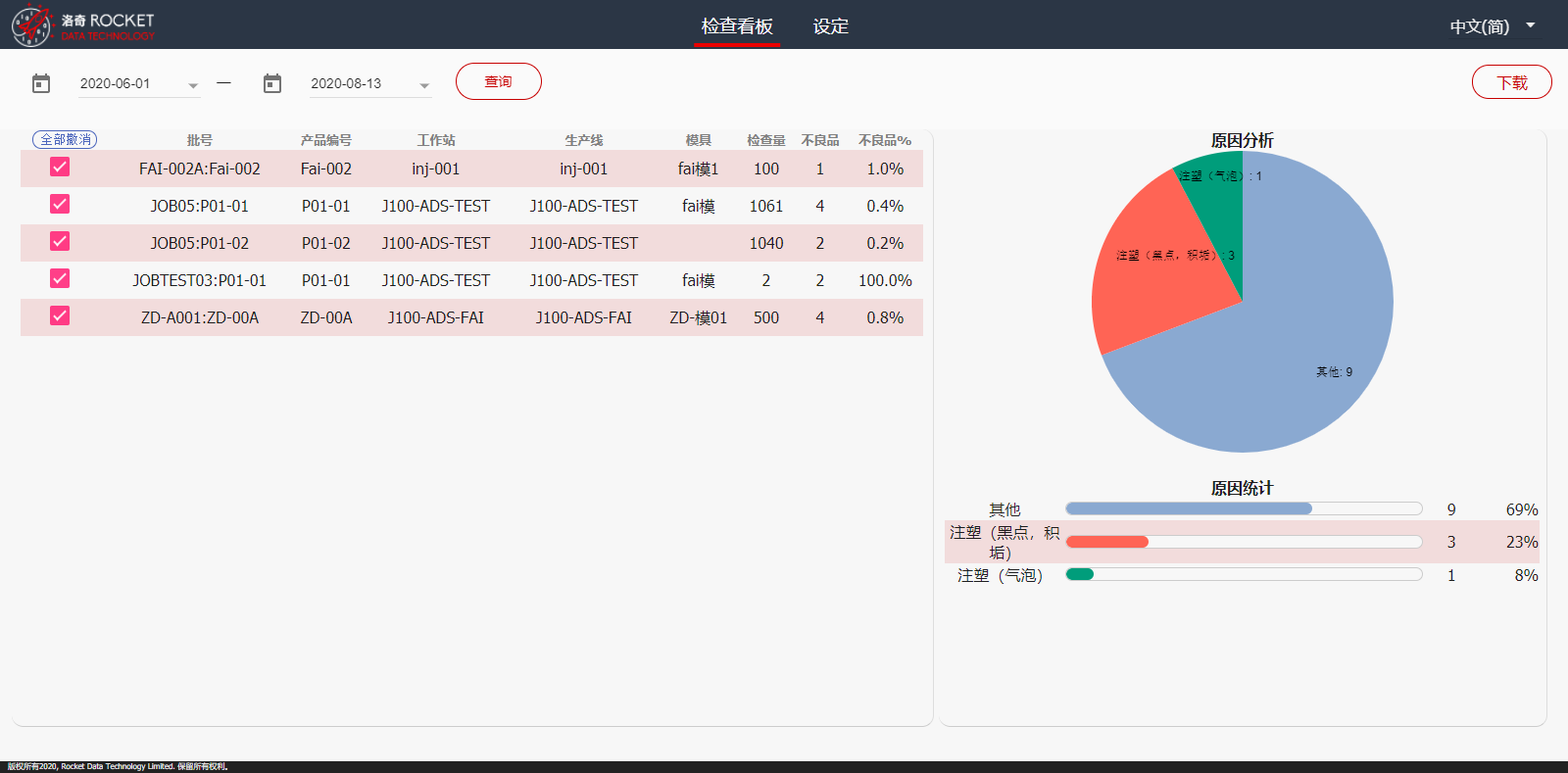

Improve Product Quality

Knowing real time machine condition/machine parameters and products defects immediately and allow user to make adjustment accordingly

Reduce Production Waste

As things are monitor in real time, production wastage and QC Reject caused by improper machine parameters will then be analysed directly

Enhance Forecast

Rocket AI APS allows user to scheduling production plan in a short time lead to forecast ahead of time and making correct decision

Improve Decision Making Ability

Real time report and analysis can be generated almost immediately, management can make better business decision

About Us

Mother company “CVI Modern Technology Development Ltd” established in the 1970s, its core business includes develop as well as market functional additives resins and processing aids target at thin film manufacturing applicants. Has two production plants (Hong Kong Tuen Mun and Malaysia respectively). With the grow of Industry 4.0, our founder brought his returnee team with more than 30 years of experience in office automation software programming, combined with rich knowledge of the plastic machinery industry and factory management experience, and worked together to cultivate core members of programming team, committed to Industry 4.0 Software development towards the international market.

EDGE IOT HARDWARE

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna.

Rocket Data Edge Computing Device (ECD)

The Rocket Data ECD is developed to be plug-and-play ready and can connect to most machines easily, regardless of type and brand. The ECD collects real-time data from the machines and those data will be processed, aggregated and time stamped within the ECD before sending it to the cloud for further analysis.

Rocket Data ECD supports various machine protocol such as OPCUA, OPCDA, Modbus TCP, Modbus RTU, Secs/Gem, Euromap, MQTT and others.

Coherent real-time dashboard

All machines status can be monitored in real-time through user friendly dashboard. High frequency data collection enables more accurate data for smart data analytics to help to reduce machine downtime and increase product efficiencies

Easy Kick Start

Rocket system is easy to kick start and can be ready to use on day 1 itself.

Future-proof

Rocket SmartPack is also integrateable with other systems such as ERP, WMS via API.

Frequently Asked Questions

What is Rocket SmartPack?

Rocket SmartPack is an Easy-to-kick-start Industry 4.0 solutions for various industry segments including injection molding, PCB, and food. It is designed and implemented with decades of experience in manufacturing and software engineering to provide real-time monitoring, management and productivity improvement for factories, production lines and equipment, help industrial enterprises to achieve digitalization quickly, and build a smart factory nowadays.

What is the expected ROI and breakeven period?

As our Rocket SmartPack is cost effective that comes along with a very short project period (days to full deployment), a 20-50x ROI can be easily expected. Do contact us for more information.

Can Rocket SmartPack integrate with other system we bought already?

Rocket SmartPack encompasses a wide spectrum of modules to support your business needs. The system and each module is ready to integrate with your existing systems or customized applications through WebService, API, and Database data transfer.

Why paper and spreadsheet a poor option for managing manufacturing?

- Extra human resource and effort are required for recording manufacturing data and performing data entry into spreadsheets

- Human errors often occur which leads to low data accuracy

- Data collection is not real-time may cause delay in decision making

- Data retrieval is difficult, labor intensive and not real-time

- As papers require documentation, storage capacity will be an issue as there is possibility of insufficient storage

- Poor documentation of papers will makes paper to be damaged easily and causing data lost in the process causing poor traceability

How do I know if Rocket SmartPack is suitable for my industry and company?

Rocket SmartPack has been vastly used by companies across various industries such as plastic injection molding, food and PCB globally. With rich manufacturing experience, we clearly understand the business needs of every company at the same time the system is also designed as such that it is easy and suitable for every industries.

What is your project implementation period?

Typically for small scale project (1-50machines) will take around 1-7days. A large scale project (>100machines) takes about 4 to 8 weeks.

What are the supports provided?

Upon deployment, intensive Rocket SmartPack training will be provided to ensure proper usage. If required, do contact us for more information.

What is Rocket Data Robot? What benefits does it brings?

Rocket Data Robot is an automatic, real-time data collection technology opening to multiple brands and models, connecting to injection machines, IoT devices, energy meters, scan guns etc:

- Collected data can be analyzed to improve products’ quality

- Machine real-time status will always be monitored and kept aware

- Notification according to different levels will be sent if the machine has stopped for a certain of time

- Collected data empower you to do data Analytics like Machine OEE and downtime statistics

How secured is our data with Rocket SmartPack in Cloud Server?

We understand data security is important to you. The Cloud Server we use is designed and managed in alignment with best security practices and a variety of security standards (ISO 9001, ISO 27001, ISO 27017, ISO 27018, Safe Harbor). We employ commercial strength SSL Certificate to protect your site and your data. Network communications and data transfer to and from your site are secured, encrypted and protected.

We have many different types and brand of machines. Can we still collect those machines’ data?

Rocket Data Robot can connect to different brands and models via machine communication protocols like Modbus RTU/TCP, OPCUA, MQTT etc and integrating them under one same interface.